Electrical installations often require specialized materials to ensure durability and safety. One such essential material is the liquid tight conduit, a versatile solution for protecting wires and cables in challenging environments.

But what is liquid tight conduit, and how can it be utilized effectively? This article explores its definition, applications, and key uses, providing a comprehensive guide on how to use liquid tight conduit for optimal results.

What Is Liquid Tight Conduit?

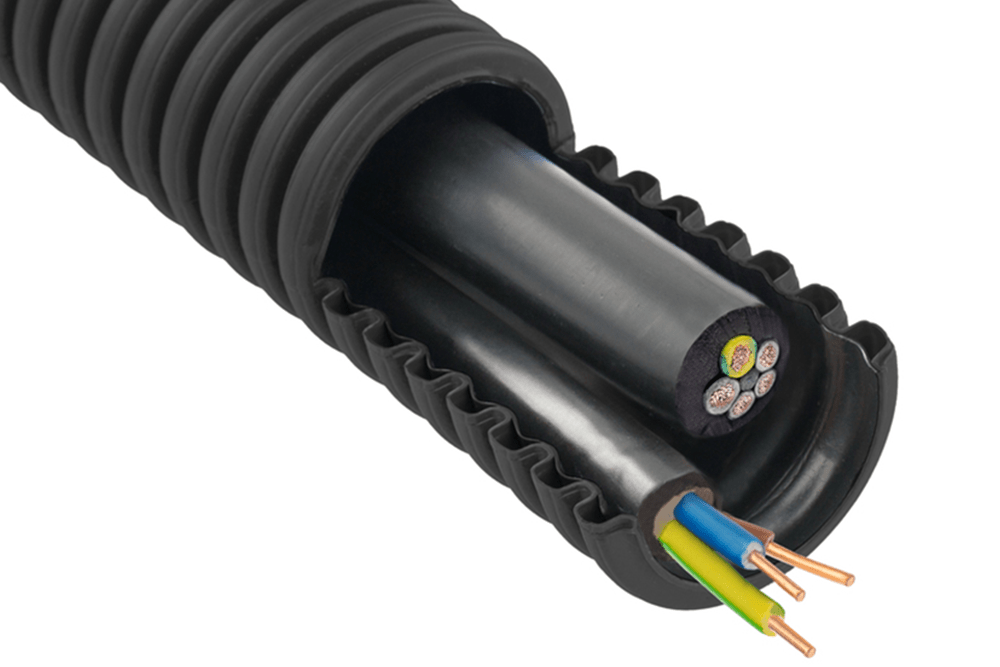

Liquid tight conduit is a type of conduit designed to protect electrical wiring from moisture, chemicals, and other environmental hazards. Its robust construction typically includes a flexible metal core surrounded by a waterproof plastic or rubber jacket. This combination makes it suitable for applications where standard conduits may fail to provide adequate protection.

Available in various sizes and configurations, liquid tight conduit is engineered for durability and ease of installation. Its unique properties make it ideal for use in both indoor and outdoor settings. With its ability to resist corrosion and withstand harsh conditions, it is a preferred choice for many professionals.

How Does Liquid Tight Conduit Work?

The key to the effectiveness of liquid tight conduit lies in its design. The flexible metal core provides strength and flexibility, allowing for easy routing in tight spaces. The outer jacket, made from materials like PVC, creates a watertight barrier, safeguarding the wires within.

Liquid tight conduits are often paired with liquid tight fittings to ensure a secure, moisture-resistant seal. This combination prevents water ingress, protecting the electrical system from short circuits and damage. Understanding how to use liquid tight conduit effectively can significantly enhance the safety and longevity of electrical installations.

Applications of Liquid Tight Conduit

- Industrial Settings

In industrial environments, liquid tight conduit is frequently used to protect wiring from exposure to oil, chemicals, and abrasion. It’s commonly found in manufacturing plants, where machinery and equipment demand reliable wiring protection. The conduit’s resilience ensures uninterrupted operations in harsh conditions.

- Outdoor Installations

Outdoor applications, such as landscape lighting and exterior wiring, benefit greatly from liquid tight conduit. Its waterproof properties shield wires from rain, snow, and humidity. Additionally, it offers protection against UV rays, extending the lifespan of the wiring system.

- HVAC Systems

Liquid tight conduit is a staple in heating, ventilation, and air conditioning (HVAC) systems. It’s used to safeguard electrical connections in air conditioners, furnaces, and other HVAC equipment. The conduit’s flexibility simplifies installation around complex machinery.

- Marine Environments

In marine settings, electrical systems are constantly exposed to saltwater and humidity. Liquid tight conduit is essential for protecting wires on boats, docks, and offshore platforms. Its corrosion-resistant properties make it a reliable choice in these demanding conditions.

How to Use Liquid Tight Conduit Effectively

- Choosing the Right Conduit

Selecting the appropriate size and type of liquid tight conduit is necessary for effective use. Consider the environmental factors and the specific requirements of your project. Ensure the conduit’s rating matches the intended application to achieve optimal performance.

- Proper Installation Techniques

Install liquid tight conduit using the correct fittings to maintain its watertight integrity. Cut the conduit cleanly and avoid sharp bends that could compromise its protective capabilities. Secure the conduit firmly to prevent movement or damage over time.

- Maintenance and Inspection

Regular inspection of liquid tight conduit is essential to ensure continued protection. Check for signs of wear, such as cracks or brittleness in the outer jacket. Promptly address any issues to prevent potential damage to the electrical system.

Benefits of Using Liquid Tight Conduit

- Enhanced Protection

Liquid tight conduit stands out for its ability to safeguard electrical wiring from harsh environmental factors, making it indispensable in many critical applications. Its waterproof design effectively seals out moisture, protecting cables and ensuring uninterrupted performance even in wet or humid conditions.

Additionally, the conduit’s chemical-resistant outer jacket prevents damage from exposure to corrosive substances, which is especially valuable in industrial and marine settings.

- Versatility

The flexibility of liquid tight conduit allows it to be used in a wide range of applications. From industrial machinery to residential outdoor wiring, its adaptability is unparalleled. This makes it a cost-effective solution for various projects.

- Ease of Installation

Liquid tight conduit combines strength with convenience, making it an excellent choice for both professionals and DIY enthusiasts. Its flexibility allows it to navigate tight corners, uneven surfaces, and complex layouts, significantly simplifying installation in challenging spaces. Whether it’s bending around machinery or fitting into cramped areas, the conduit’s design ensures adaptability without compromising its protective qualities.

Liquid Tight Conduit Vs. Other Types of Conduit

- Rigid Metal Conduit (RMC)

While rigid metal conduit offers excellent durability, it lacks the flexibility of liquid tight conduit. RMC is better suited for straight runs in heavy-duty applications. In contrast, liquid tight conduit excels in environments requiring flexibility and moisture resistance.

- Flexible Metal Conduit (FMC)

Flexible metal conduit provides good flexibility but lacks the waterproof properties of liquid tight conduit. It’s suitable for indoor use but not ideal for environments with high moisture levels. Liquid tight conduit combines the benefits of flexibility and waterproofing, making it more versatile.

- Plastic Conduit

Plastic conduits are lightweight and resistant to corrosion but are not as durable as liquid tight conduit. They are prone to damage in high-stress environments. Liquid tight conduit offers a more robust solution for protecting electrical wiring.

Common Mistakes to Avoid

- Using Incorrect Fittings

Improper fittings can compromise the watertight seal of the conduit. Always use fittings specifically designed for liquid tight conduit to ensure optimal performance.

- Overlooking Environmental Factors

Failing to consider environmental conditions can lead to premature failure of the conduit. Select materials and ratings suitable for the specific application to avoid costly repairs.

- Neglecting Regular Maintenance

Skipping regular inspections can result in unnoticed damage, compromising the protection of your electrical system. Schedule routine checks to identify and address potential issues promptly.

Protect Your Electrical Installations Today

Liquid tight conduit is an indispensable tool for safeguarding electrical systems in challenging environments. Whether you’re working on industrial machinery, outdoor wiring, or HVAC systems, this versatile conduit offers unmatched protection and reliability.

Whether you’re looking for a metallic liquid tight conduit, non-metallic liquid tight conduit, or a non-metallic liquid tight 90° connector, Sonic Electric has everything you need. Shop our top-quality products today!

Share:

Understanding Electrical Wire Types And Uses

When To Replace A Circuit Breaker: 8 Warning Signs