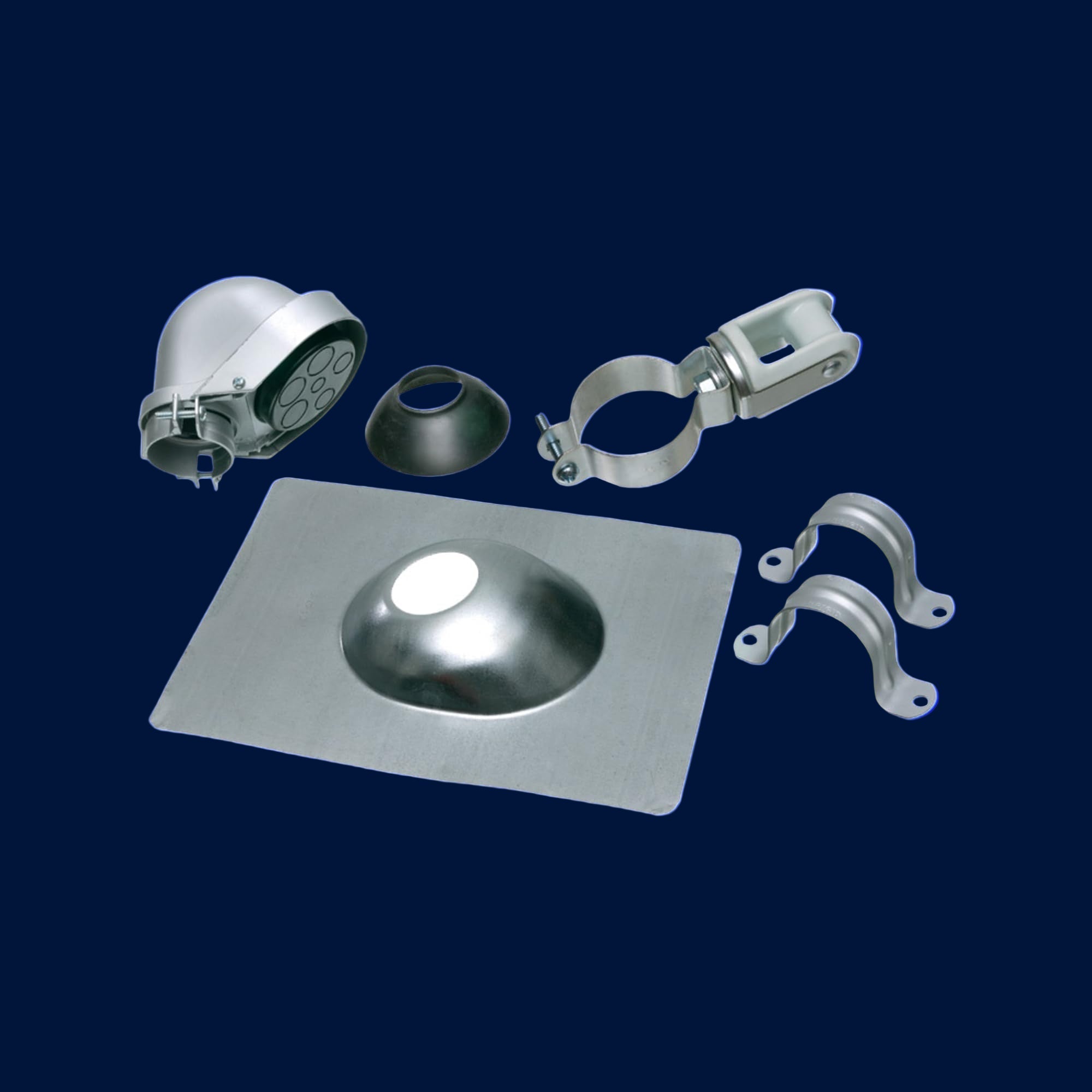

When installing rigid metal conduit (RMC) systems, choosing the right connectors and couplings is essential for code compliance, safety, and performance. At Sonic Electric, we supply both rigid threaded and threadless options — each designed for specific jobsite needs. Here's a breakdown of the differences, applications, and how to select the right type for your project.

What Are Rigid Connectors and Couplings?

Rigid connectors and couplings are fittings used to join sections of rigid conduit (usually galvanized steel or aluminum), or to terminate conduit into enclosures, panels, or boxes. They ensure electrical continuity and physical support, while protecting conductors.

There are two primary types:

-

Threaded: Requires threads cut into the conduit.

-

Threadless: Slides over unthreaded conduit and is secured with set screws or compression fittings.

Threaded Connectors & Couplings

Applications:

-

Used with threaded rigid metal conduit (RMC)

-

Common in industrial, heavy commercial, or hazardous locations

-

Provides a mechanically secure and grounded connection

-

Often used in environments requiring superior protection against physical damage

Available Sizes:

-

1/2" through 6"

-

Most common: 1/2", 3/4", 1", 1-1/4", 1-1/2", 2"

Advantages:

-

Threaded connection resists vibration

-

Ensures strong bonding and grounding

-

Often required in Class I Division 1 hazardous locations per NEC

Installation Note:

-

Requires a threader or pre-threaded conduit

-

Must use thread sealant for wet or corrosive environments

Threadless Connectors & Couplings

Types:

-

Set-Screw Type: Uses screws to secure to the conduit

-

Compression Type: Uses a compression ring and nut for a watertight seal

Applications:

-

Used with non-threaded RMC or IMC (intermediate metal conduit)

-

Ideal for commercial buildings, garages, and surface-mounted systems

-

Often used for above-ground conduit runs in dry or damp locations

Available Sizes:

-

1/2" through 4"

-

Most common: 1/2", 3/4", 1", 1-1/2", 2"

Advantages:

-

Faster to install — no threading required

-

Cleaner appearance in finished spaces

-

Compression versions are suitable for wet locations

Installation Note:

-

Set-screw types are typically for dry locations only

-

Always check UL listing and NEC compliance

Why Are There Two Types?

The choice between threaded and threadless comes down to:

-

Jobsite needs

-

Speed of installation

-

Environment (dry, wet, hazardous)

-

Code compliance

Threaded systems are preferred in industrial and hazardous locations due to their mechanical strength and grounding reliability. Threadless systems, on the other hand, offer installation speed and flexibility, especially in commercial builds where conduit is run indoors.

Choosing the Right Connector or Coupling

| Jobsite Environment | Recommended Type | Reason |

|---|---|---|

| Dry Indoor | Threadless (Set-Screw) | Quick install, no threading needed |

| Wet Location | Threadless (Compression) | Watertight seal |

| Hazardous Location | Threaded | NEC-compliant for grounding |

| Outdoor Above Ground | Threaded or Threadless Compression | Depends on location and code |

| Industrial Plant | Threaded | Maximum durability |

Final Tips

-

Always match conduit type (RMC or IMC) to the appropriate fitting

-

Verify NEC requirements for specific environments (e.g., Class I, II, III)

-

Check UL listings for wet/dry location ratings

-

Use anti-oxidant compound for aluminum conduit connections

-

Stock common sizes (½" to 2") for most jobs

Rigid Connectors & Couplings Available at Sonic Electric

Whether you need threaded steel couplings for a heavy-duty industrial job or compression connectors for a commercial install, Sonic Electric carries a full line of fittings in-stock and ready to ship. Our team is here to help you find the right product for your project — fast, fair, and reliable.

Need help selecting the right connector or coupling?

Call us at (323) 934-3744 or visit SonicElectric.com to browse our full inventory.

Share:

LED Flexible Sheet Lighting – Pro Guide to Clean Installs, Drivers & Ideal Applications

A Step-By-Step Guide To Circuit Breaker Installation