Electrical systems require reliable solutions to protect wiring from damage, wear, and environmental challenges. Conduits—whether metallic or non-metallic—serve as shields that preserve the integrity of these systems while promoting safety and reliability. Choosing between metallic vs. non-metallic conduit depends on several factors, such as cost, strength, flexibility, and the specific demands of your project.

At Sonic Electric, we’ve supplied high-quality electrical products for over 40 years. With our extensive selection of metallic and non-metallic conduits, we help customers tackle various applications confidently. This guide explores the differences between these two types of conduit, their ideal use cases, and how to make the right choice.

Understanding Metallic Vs. Non-Metallic Conduit

Both metallic and non-metallic conduits protect and route electrical wiring. However, they differ in their composition, properties, and applications. Metallic conduits are primarily made of steel, aluminum, or other metals, while non-metallic conduits use PVC, HDPE, or other durable plastics. These material differences translate into distinct advantages and limitations for each type.

Metallic conduits are celebrated for their durability, fire resistance, and ability to handle extreme conditions. They are commonly used in industrial environments, where heavy-duty protection is necessary. Conversely, non-metallic conduits excel in areas where corrosion resistance, flexibility, and lightweight materials are more important.

They are perfect for residential and commercial installations where cost and ease of installation are significant factors. Both types of conduit come in liquid-tight versions, which makes them suitable for wet environments, outdoor lighting, and buried applications.

Advantages of Metallic Conduit

Metallic conduit is synonymous with strength and longevity. It offers protection against physical damage and is a staple in high-traffic and industrial environments. Its ability to withstand extreme temperatures makes it a versatile choice for demanding projects. Metallic conduit is also non-combustible. This feature adds a layer of safety in applications where fire resistance is a priority.

The rigid construction of metallic conduits guarantees that they remain intact under significant mechanical stress. This makes them ideal for exposed installations, such as building walls, ceilings, and industrial machinery. Additionally, metallic conduits can act as grounding paths. They can support safe electrical systems without requiring additional grounding wires.

Metallic liquid-tight conduit also provides protection for projects requiring moisture resistance. Its polymer jackets add an extra layer of durability to withstand wet conditions, burial underground, and even installation in concrete.

Benefits of Non-Metallic Conduit

Non-metallic conduit is lightweight, flexible, and highly resistant to corrosion. It is an excellent option for applications in harsh environments. Materials like PVC and HDPE offer natural resistance to rust and water damage. This can maintain longevity in settings like swimming pools, outdoor wiring, or areas with high humidity. Its lightweight nature simplifies installation, especially in projects requiring extensive routing through tight or awkward spaces.

Non-metallic conduits are also highly versatile. They are suitable for both indoor and outdoor applications, including residential wiring, HVAC systems, and underground installations. Their flexibility allows them to be easily cut and adjusted on-site.

However, non-metallic conduits are not as strong as metallic options. Hence, they are less suitable for areas prone to heavy impacts or extreme temperatures. They are also more susceptible to deformation under mechanical stress. Despite these limitations, non-metallic conduits remain a cost-effective and practical solution for many standard applications.

Comparing Metallic Vs. Non-Metallic Liquid-Tight Conduit

Both metallic and non-metallic liquid-tight conduits excel in similar applications. However, they differ significantly in performance and suitability.

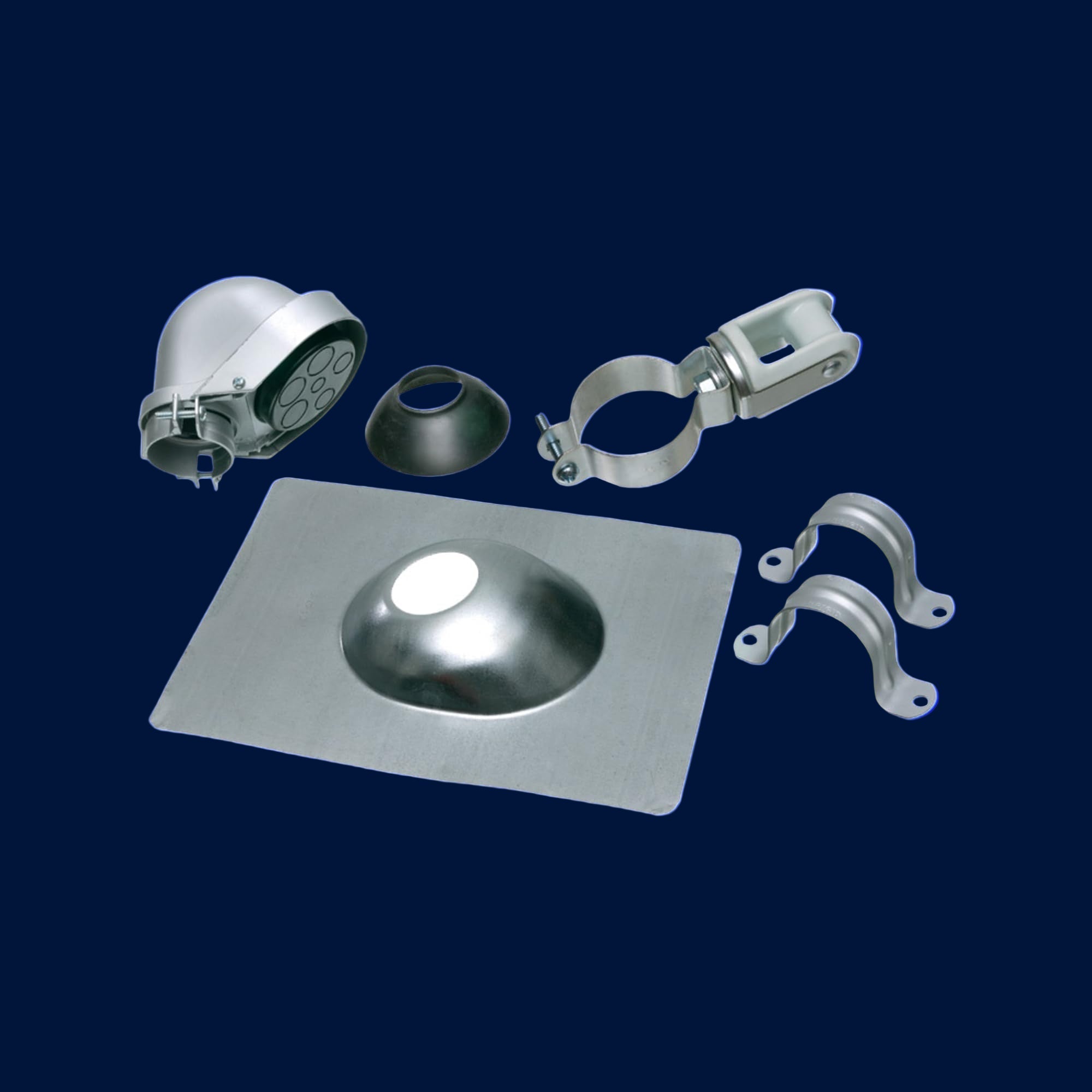

Metallic liquid-tight conduit combines the strength of metal with the flexibility and moisture resistance of polymer coatings. This makes it ideal for industrial environments, high-vibration areas, and projects requiring heavy-duty impact resistance. Its durability guarantees reliable performance in even the harshest conditions, such as manufacturing plants or outdoor equipment.

On the other hand, non-metallic liquid-tight conduit prioritizes corrosion resistance and flexibility. It is lightweight and easy to install. Thus, it is widely used in residential and commercial applications where secure, watertight connections are essential. For example, our non-metallic liquid-tight 90° connector allows for secure, watertight connections in tight spaces.

The choice between these two types of liquid-tight conduit ultimately depends on your project’s requirements. If durability and impact resistance are your primary concerns, metallic options are the way to go. Non-metallic conduits provide excellent value for lightweight, corrosion-proof solutions.

Key Considerations for Choosing the Right Conduit

When selecting a conduit, evaluate the specific demands of your project. The environment plays a significant role in determining the best option. Industrial settings with heavy machinery, vibrations, and high temperatures often require the reliability of metallic conduit. In contrast, residential or commercial installations benefit from the flexibility and cost-effectiveness of non-metallic options.

Cost is another important factor. While metallic conduit tends to be more expensive upfront, its durability and long lifespan often justify the investment for long-term projects. Non-metallic conduits are more affordable and easier to install, so they are ideal for projects with tight budgets or less demanding environments.

Both metallic and non-metallic conduits must comply with the National Electrical Code (NEC) and other local regulations for proper performance and safety. For example, certain non-metallic conduits cannot be used in plenum spaces due to flammability. Another regulation is that metallic conduits require polymer coatings for use in corrosive or wet environments.

Sonic Electric Is Your Trusted Source for Conduit Solutions

At Sonic Electric, we deliver high-quality electrical products that meet our customers' diverse needs. If you’re looking for the strength and durability of metallic liquid-tight conduit or the flexibility of non-metallic liquid-tight conduit, we have you covered.

With decades of experience and a commitment to excellence, we provide products that excel in performance, reliability, and safety. Browse our wide range of conduit solutions and find the perfect fit for your next project.

Share:

How To Replace An LED Recessed Light Properly

Understanding Electrical Wire Types And Uses