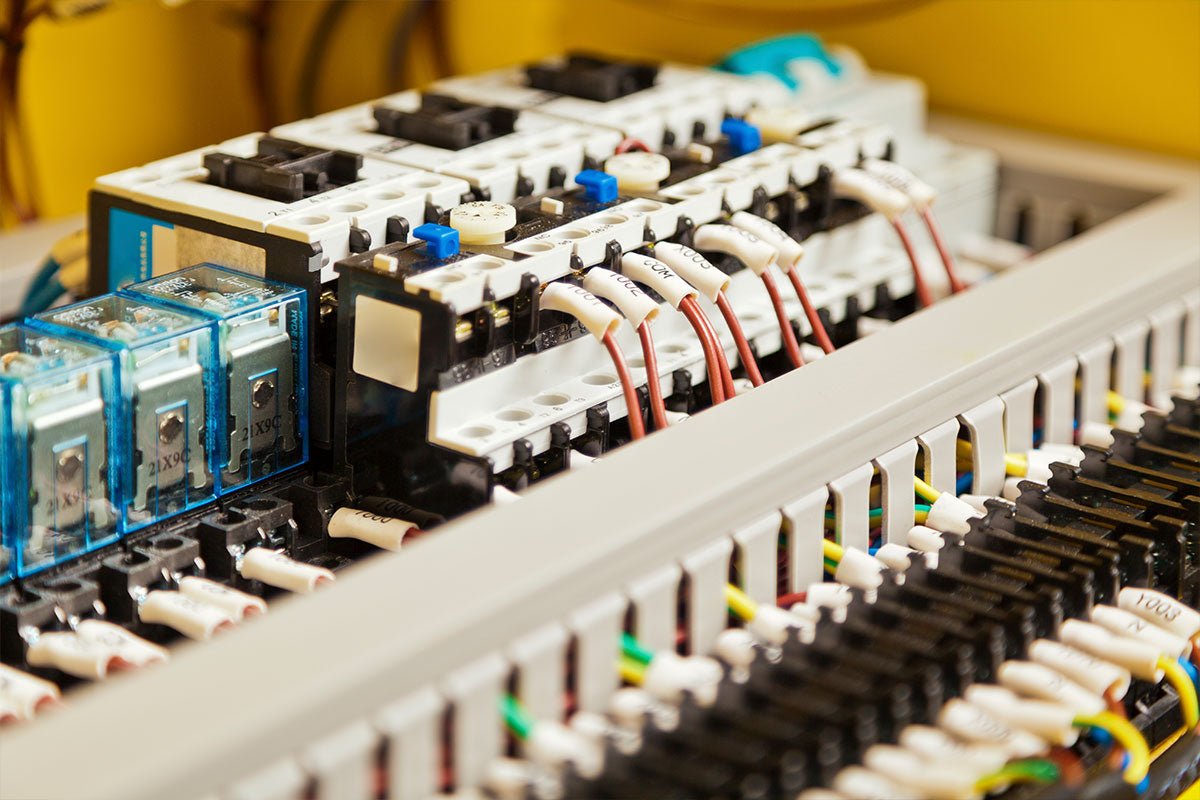

Electrical connectors play an invaluable role in numerous wiring scenarios, assuring secure and efficient electrical connections across various applications. These connectors serve as important components that facilitate the transfer of power and signals. They help guarantee reliability and safety within electrical systems. Understanding the many types of electrical connectors is helpful because they cater to specific requirements. This aspect provides versatility when addressing various installation needs.

For example, compression connectors - characterized by their ability to withstand high levels of pressure - provide a reliable and durable connection. They're particularly useful in environments where vibration or movement might otherwise compromise the integrity of the connection. MC connectors, on the other hand, serve a different purpose. They offer protection and insulation in metal-clad cable installations. Their design guarantees a secure fit, safeguarding against potential electrical hazards.

Still other examples - such as liquid-tight connectors - are invaluable in situations that require protection against moisture, water, or other liquids. These connectors create a seal that prevents ingress (when unwanted water gets in), safeguarding electrical connections in damp or wet environments. Similarly, split bolt connectors, known for their versatility, provide a strong connection between multiple wires, providing efficient electrical conductivity.

Looking closely at twist-on wire connectors, you’ll notice their simplicity and ease of use in joining or terminating wires. They offer a convenient solution for quick installations and repairs. Finally, pin and sleeve connectors, commonly used in industrial settings, assure a secure, lockable connection perfect for high-power applications.

Understanding the distinctions and applications of electrical connectors gives people the power to choose the most appropriate option for their specific wiring needs. Each connector type comes with its unique features, better assuring reliability, efficiency, and safety in electrical installations across a vast array of environments and industries.

Compression Connectors

Compression connectors are true champions in the world of electrical connections, appreciated for their unmatched capacity to establish strong and enduring links. Operating on the principle of harnessing compression force, these connectors smoothly unite conductors, providing an unwavering solution specifically designed for high-voltage applications. Their sturdy makeup serves as a defense against the dangers of corrosion, guaranteeing prolonged durability and heightened conductivity. This unique combination of characteristics makes compression connectors indispensable in the area of power transmission and distribution systems. Here, reliability and efficiency stand as critical requirements.

These connectors boast a construction engineered with precision and durability at its core. Made to endure the rigors of high-voltage environments, they offer a resilience that safeguards against the adverse effects of environmental factors. Their design specifically minimizes the potential for corrosion, thereby lengthening their lifespan and preserving their conductivity at optimal levels. This attribute not only assures a steadfast connection but also reduces the need for frequent maintenance. So, they contribute greatly to operational efficiency and cost-effectiveness in large-scale electrical systems.

What’s more, the application versatility of compression connectors underscores their indispensability in any number of electrical setups. From overhead power lines to underground distribution networks, these connectors serve as linchpins. They allow seamless transmission and distribution of electrical power across numerous infrastructural situations. Their adaptability to different conductor materials and sizes further stresses their utility, catering to a wide spectrum of requirements across the electrical industry.

The process of establishing a connection through compression connectors involves a carefully engineered sequence. The application of controlled compression force is vital, guaranteeing a secure and strong connection between conductors. This method not only increases the structural integrity of the joint but also lessens the risks associated with loosening or disconnection due to external factors.

All in all, compression connectors are clearly some of the most critical components within the world of electrical systems. They are appreciated for their reliability, durability, and unwavering performance in high-voltage applications. Their sturdy construction, combined with impeccable conductivity, cements their status as important assets in facilitating efficient power transmission and distribution networks across a variety of infrastructural settings.

MC Connectors

MC connectors also play a big part within electrical systems, particularly in the context of armored cables. These connectors serve as reliable mechanisms for establishing secure connections within metal-clad (MC) wiring systems. The basic purpose they serve is to assure a steadfast grip on the cable's metal sheath - safeguarding against potential damage while also upholding the essential electrical integrity of the system.

Within the world of industrial and commercial installations, MC connectors exist as indispensable components thanks to their multifaceted functionalities. They provide a dual advantage by providing both grounding and protection. This dual functionality becomes highly important in maintaining safety standards and operational efficiency in these settings.

Their design specs are tailored to cater specifically to the challenges posed by metal-clad cables. By securely fastening onto the cable's metal sheath, these connectors effectively reduce the risks of disconnection or damage caused by environmental factors or unintentional physical disturbances. This strong attachment guarantees a steadfast electrical continuity that is critical for uninterrupted operations within numerous applications.

The grounding feature of MC connectors contributes greatly to the overall safety of the electrical system. By establishing a reliable path to ground, these connectors effectively divert potentially hazardous currents, thereby lessening the risk of electrical faults or short circuits. This imperative function not only protects equipment and infrastructure but also minimizes the possibility of electrical hazards, providing a safer environment for both personnel and assets.

The versatility and reliability of MC connectors make them an integral part of any number of electrical installations. Their compatibility with metal-clad cables heightens the overall resilience of these systems, making them well-suited for demanding industrial and commercial environments where electrical reliability is critical.

Remember, the significance of MC connectors goes well beyond mere connectivity. They serve as protectors of the electrical infrastructure, fortifying systems against potential risks while assuring steadfast electrical continuity and safety. Their undeniable role within metal-clad wiring systems underscores their importance in maintaining the efficiency, safety, and reliability of numerous electrical applications across industrial and commercial sectors.

Liquid Tight Connectors

Liquid-tight connectors are important components in situations where electrical connections are exposed to moisture, water, or harsh environmental conditions. Their construction with sealing gaskets and secure fittings is critical. It forms a barrier against water ingress, preventing potential electrical hazards such as short circuits or corrosion.

These connectors are versatile, finding extensive use in any number of industries. In outdoor lighting setups, they shield electrical connections in garden lights, landscape fixtures, or streetlamps from rain and humidity. Marine environments heavily rely on these connectors to guard shipboard electrical systems against saltwater exposure, which can be highly corrosive.

Overall, in industrial settings like manufacturing plants or warehouses where machinery and equipment might encounter moisture, dust, or other contaminants, liquid-tight connectors are used to maintain electrical safety and reliability.

Their design diversity goes along with different cable sizes and configurations, guaranteeing compatibility across a vast array of applications. From flexible conduits to armored cables, these connectors provide a secure, moisture-resistant interface for electrical connections.

Regular inspections and maintenance are important to uphold the effectiveness of these connectors, making sure they remain intact and functional to continue with their protective capabilities over time.

Split Bolt Connectors

Split bolt connectors are invaluable components in electrical systems, known for their exceptional ability to join conductors made of copper or aluminum. Made with a sturdy design and boasting a considerable clamping force, these connectors prove their worth in heavy-duty applications where reliable connections are non-negotiable. Their versatility applies to a wide selection of situations, making them a staple in electrical installations across industries.

One of the basic functions of split bolt connectors lies in their important role within electrical grounding systems. By providing a secure connection between conductors, they create a low-resistance pathway for fault currents. This is a critical safety measure that helps redirect and manage excess electrical currents, preventing potential hazards like short circuits, electrical fires, or equipment damage. This integral safety feature heightens the overall reliability of electrical setups where split bolt connectors are used.

Their efficacy doesn’t stop at safety, however. Split bolt connectors also provide consistent and uninterrupted electrical conductivity. This reliability is particularly important in environments where fluctuations or interruptions in electrical flow are unacceptable. Whether in industrial machinery, power distribution units, or residential electrical systems, the dependable performance of split bolt connectors remains unmatched.

Also, the durability of these connectors is worth mentioning. Made from high-quality materials and engineered to withstand environmental stressors, they offer longevity even in harsh conditions. This resilience helps to guarantee sustained functionality over extended periods. This contributes to cost-efficiency by reducing the need for frequent replacements or maintenance.

The ease of installation adds to their appeal. Designed for straightforward setup, split bolt connectors simplify the connection process, reducing installation time and effort. This user-friendly characteristic makes them accessible even to those without extensive technical expertise. This promotes convenience without compromising on effectiveness.

In summary, split bolt connectors stand as major, dependable components within electrical systems. They provide a trifecta of reliability, safety, and ease of use. Their ability to create secure, low-resistance connections between conductors - combined with their durability and user-friendly design - solidifies their position as indispensable assets in many electrical applications.

Wire Connectors

Wire connectors, also known as twist-on connectors, offer a simple and efficient way to join electrical wires. Available in various sizes and colors, these connectors twist multiple wires together, creating a secure bond. They are versatile, cost-effective, and widely used in residential, commercial, and industrial electrical connections.

Butt Connectors

Butt connectors are indispensable components when it comes to establishing seamless connections between two wires, joining them end-to-end with precision and reliability. These connectors - available in an array of types such as crimp-style and heat-shrink variants - play a big part in creating a durable, insulated joint that guarantees optimal performance and safety.

In the world of electrical connections, these connectors are a staple, particularly known for their application in automotive wiring, audio systems, and telecommunications. Their versatility and efficacy make them a go-to choice across a wide selection of industries and settings.

Crimp-style butt connectors, for example, boast a design that allows for the secure fastening of wires through the use of a crimping tool. This method assures a tight and lasting connection, reducing the risk of loosening or disconnection over time. The range of sizes available in crimp-style connectors caters to different wire gauges, accommodating a number of wiring needs with ease and precision.

On the other hand, heat-shrink butt connectors offer an additional layer of protection. They not only establish a reliable electrical connection but also feature a heat-activated shrinkage mechanism. When heat is applied (often through the use of a heat gun or torch) the insulating material encasing the connector contracts, forming a tight seal around the wires. This heat-induced sealing process not only provides insulation against environmental factors but also guards against moisture, corrosion, and other potential hazards.

The significance of butt connectors in maintaining electrical conductivity while assuring insulation cannot be overstated. Their role in safeguarding connections against electrical interference, vibrations, and mechanical stress is critical in maintaining the integrity and longevity of electrical systems.

Whether in automotive applications, audio setups, telecommunications networks, or various other electrical projects, the reliability and efficiency of butt connectors remain unmatched. Their ability to combine smooth connectivity with lasting insulation continues to make them an invaluable component across a vast array of industries, assuring the continuous flow of power and information in countless applications.

Other Connectors

In addition to the above-mentioned connectors, there are a number of specialized connectors that cater to specific applications. These include pin-and-sleeve connectors for industrial power distribution, terminal blocks for control wiring, and DIN connectors for electronic devices. Each serves a precise purpose, contributing to the diversity of electrical connections across numerous industries.

The wide selection of electrical connectors available in the market caters to any and all wiring needs, guaranteeing safety, reliability, and efficiency in electrical systems. Understanding the distinct features and applications of different types of electrical connectors helps professionals and DIY enthusiasts alike to make better choices for their specific wiring requirements.

By exploring the distinct characteristics and applications of various types of electrical connectors—such as compression, MC, liquid-tight, split bolt connectors, wire connectors, butt connectors, and other specialized variants—you can appreciate the big part they play in assuring secure and efficient electrical connections across diverse industries and applications.

Need a Specific Type of Connector? Sonic Electric Has What You Need

Sonic Electric has the connector you’ve been searching for… and so much more.

If your hunt for the perfect connector has hit a roadblock or you require a pricing estimate, rest assured, our dedicated team is committed to assisting you in discovering precisely what you seek - even if it isn't currently available in our inventory. With a simple phone call or email, we pledge to surpass expectations by sourcing the exact product you need and swiftly delivering it to you.

Don't hesitate to put us to the test! Reach out to us at (323) 934-3744 or drop a message at hello@sonicelectric.com detailing your product query, and we'll promptly furnish you with a customized quote. At Sonic Electric, our foremost objective is to make sure your shopping journey is effortless and devoid of stress, showcasing our unwavering commitment to your satisfaction.

Share:

How To Install Recessed Lighting Like A Pro

A Guide to Buying All Types of Electrical Conduit Fittings